9.15 GMAW/FCAW Troubleshooting Guide

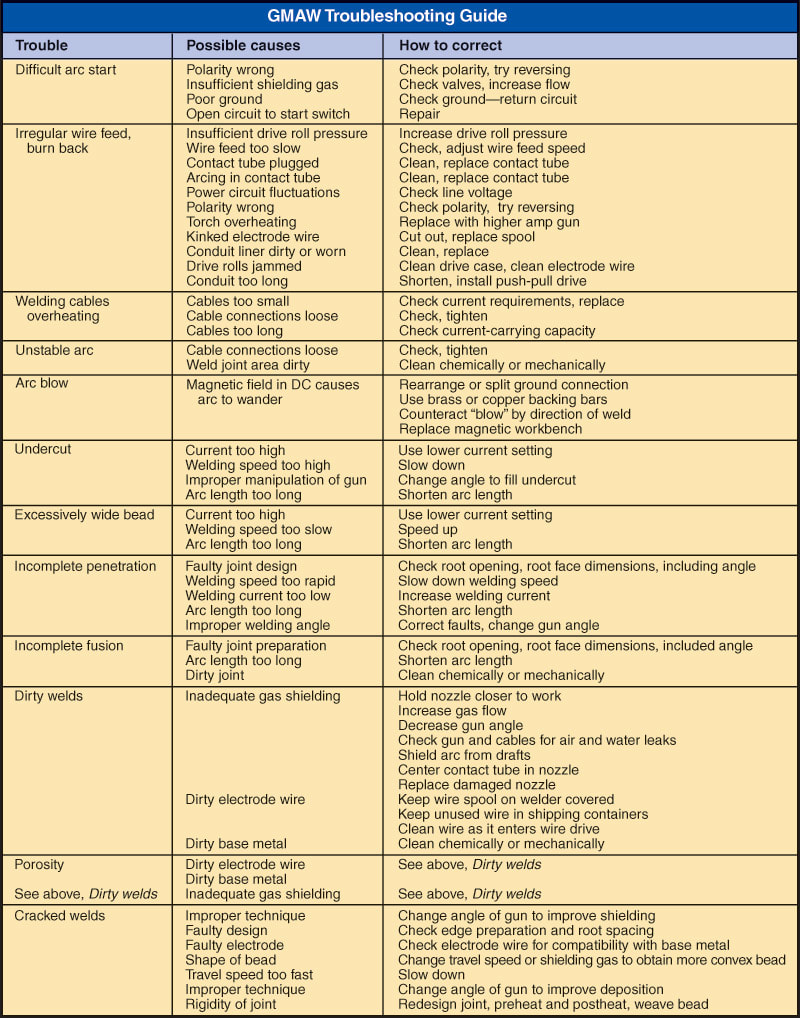

Figure 9-66 is a chart that describes many typical troubles that may occur when a gas metal arc weld is being made. The possible causes of each problem are shown along with corresponding methods for correcting each cause.

To use this chart, find the problem in the left column. The center column lists possible causes of the problem. Methods to correct the problem are listed in the third column.

When troubleshooting, first identify items that are known to cause a problem and are easy to correct. These include removing spatter from the nozzle, replacing a worn contact tube, and making sure the correct shielding gas and flow rate are being used. These common causes of problems should be checked first, especially if the equipment was making good welds prior to issues arising.

A second set of causes to check are the equipment setup and welding technique. These include items like wire feed speed, voltage settings, too long an arc length, or improper gun angles or travel speed.

If a cause is still not found after checking these items, check the more difficult items which may include worn cables, grounding issues, problems with the equipment, or problems with the design of the weld.

To use this chart, find the problem in the left column. The center column lists possible causes of the problem. Methods to correct the problem are listed in the third column.

When troubleshooting, first identify items that are known to cause a problem and are easy to correct. These include removing spatter from the nozzle, replacing a worn contact tube, and making sure the correct shielding gas and flow rate are being used. These common causes of problems should be checked first, especially if the equipment was making good welds prior to issues arising.

A second set of causes to check are the equipment setup and welding technique. These include items like wire feed speed, voltage settings, too long an arc length, or improper gun angles or travel speed.

If a cause is still not found after checking these items, check the more difficult items which may include worn cables, grounding issues, problems with the equipment, or problems with the design of the weld.