7.8 Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW) Welding Stations

Gas metal arc welding and flux cored arc welding both use continuously fed wires. The wire is the electrode. The continuously fed electrode is melted by the arc which is struck between the electrode and the base metal. The melted electrode wire enters the weld and becomes filler metal. Gas metal arc welding and flux cored arc welding are semiautomatic welding processes and are often automated or mechanized. Gas metal arc welding uses a shielding gas to protect the weld and weld area.

The flux cored arc welding (FCAW) process is only used to weld ferrous metals and nickel-based alloys. Ferrous metals are those with iron as the main element. Flux cored arc welding is very similar to gas metal arc welding. The difference is in the metal electrode that is used. Flux cored electrode wire is tubular. The hollow center of the electrode is filled with fluxing ingredients and alloying elements. In the FCAW process, the weld is shielded from atmospheric contamination by one of two methods.

The flux cored arc welding (FCAW) process is only used to weld ferrous metals and nickel-based alloys. Ferrous metals are those with iron as the main element. Flux cored arc welding is very similar to gas metal arc welding. The difference is in the metal electrode that is used. Flux cored electrode wire is tubular. The hollow center of the electrode is filled with fluxing ingredients and alloying elements. In the FCAW process, the weld is shielded from atmospheric contamination by one of two methods.

|

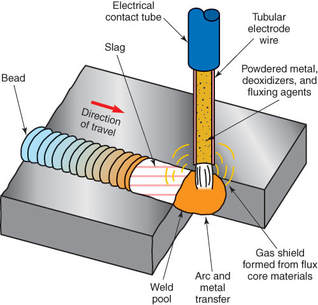

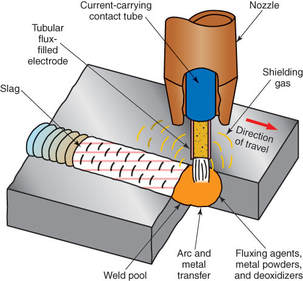

Self-shielded flux cored arc welding (FCAW-S) shields the weld with gases formed when the fluxing agents within the hollow electrode vaporize in the heat of the arc. See Figure 7-29. A second method is called gas-shielded flux cored arc welding (FCAW-G). In this method, a shielding gas, of carbon dioxide or a combination of argon and carbon dioxide, is used in addition to the vaporizing flux in the electrode core. See Figure 7-30.

Flux cored arc welding combines the benefits of shielded metal arc welding (SMAW), submerged arc welding (SAW), and gas metal arc welding (GMAW). These include:

Flux cored arc welding is generally performed semiautomatically. For semiautomatic welding, the welding gun is held and manipulated by the welder. Flux cored arc welding can also be used on fully automatic machines with excellent results. |

Self-shielded flux cored arc welding (FCAW-S) gives better results than gas-shielded flux cored arc welding (FCAW-G/GM) when cross winds are present. The shielding gas for gas-shielded FCAW could be disturbed or removed by a cross wind. This would result in poor welds. The self-shielded FCAW process is also preferred for welding in hard-to-reach or hard-to-see places. Since there is no shielding gas, there is no nozzle, so visibility is improved. The electrode extension may be greater. Moving the arc out and away from the electrode contact tube permits the welder to see the joint more easily.

7.8.1 GMAW Arc Welding Station

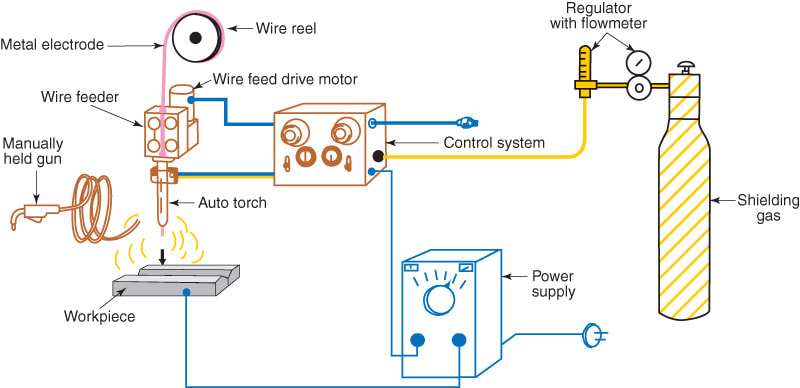

Gas metal arc welding (GMAW) uses the equipment listed in next column to make a weld. A gas-shielded flux cored arc welding station uses exactly the same equipment. In the GMAW process, a continuous wire electrode is fed into the weld. As the electrode melts, it also melts the base metal to form a weld.

A typical GMAW outfit contains the following equipment and supplies:

Gas metal arc welding (GMAW) uses the equipment listed in next column to make a weld. A gas-shielded flux cored arc welding station uses exactly the same equipment. In the GMAW process, a continuous wire electrode is fed into the weld. As the electrode melts, it also melts the base metal to form a weld.

A typical GMAW outfit contains the following equipment and supplies:

- A constant voltage dc arc welding power source.

- An electrode wire feed mechanism.

- Shielding gas cylinders.

- A gas regulator.

- A shielding gas flowmeter.

- Shielding gas, coolant hoses and fittings, and the electrode and workpiece leads.

- A GMAW welding gun.

- Electrode wire.

- A coolant system. See Figure 7-10.

- Remote controls.

- A booth, table, and ventilation system.

Figure 7-31 is a schematic drawing of a GMAW outfit. A complete station would include the arc welding booth, a ventilation system, and a welding bench.

7.8.2 FCAW Arc Welding Station

The equipment required for a gas-shielded flux cored arc welding station is identical to the equipment used for gas metal arc welding. Since the equipment is identical, the same equipment can be used for both processes. Self-shielded flux cored arc welding uses a different torch and does not use any shielding gas equipment. The following equipment is required for FCAW welding stations:

Optional equipment:

The gun for self-shielded FCAW may be air-cooled or water-cooled. Air-cooled guns are generally used with up to 200A of current. Water-cooled guns are used when using currents of more than 200A. Water cooling is also used on guns that operate on a 100% duty cycle.

Flux cored arc welding electrodes are tubular and easily flattened. The wire drive wheels used for FCAW are usually knurled to firmly grip, but not crush, the tubular electrodes. These drive wheels must be carefully adjusted to permit the wire to be driven, but not flattened.

The equipment required for a gas-shielded flux cored arc welding station is identical to the equipment used for gas metal arc welding. Since the equipment is identical, the same equipment can be used for both processes. Self-shielded flux cored arc welding uses a different torch and does not use any shielding gas equipment. The following equipment is required for FCAW welding stations:

- A constant voltage dc arc welding power source.

- An electrode wire feed mechanism.

- Shielding gas cylinders*.

- A gas regulator*.

- A shielding gas flowmeter*.

- Shielding gas and coolant hoses and fittings*.

- Electrode lead and workpiece lead.

- An FCAW or GMAW (for FCAW-G/GM) welding gun.

- Flux cored metal electrode wire.

Optional equipment:

- A coolant system.

- Remote controls.

- A booth, table, and ventilation system.

The gun for self-shielded FCAW may be air-cooled or water-cooled. Air-cooled guns are generally used with up to 200A of current. Water-cooled guns are used when using currents of more than 200A. Water cooling is also used on guns that operate on a 100% duty cycle.

Flux cored arc welding electrodes are tubular and easily flattened. The wire drive wheels used for FCAW are usually knurled to firmly grip, but not crush, the tubular electrodes. These drive wheels must be carefully adjusted to permit the wire to be driven, but not flattened.