7.5 GTAW Torches

Gas tungsten arc welding torches come in many different designs, sizes, amperages, and shapes. Torches designed for lower amperages and light-duty use are cooled by the shielding gas flowing through the torch. Current capacity for the largest shielding gas-cooled torches is about 200A. Smaller gas-cooled torches carry significantly less current.

Torches used for higher amperages and those that are used to do a lot of welding at lower amperages are water-cooled. Most torches used in production and most torches used for continuous automatic welding are water-cooled. Figure 7-16 presents a side-by-side comparison of gas-cooled and water-cooled torches.

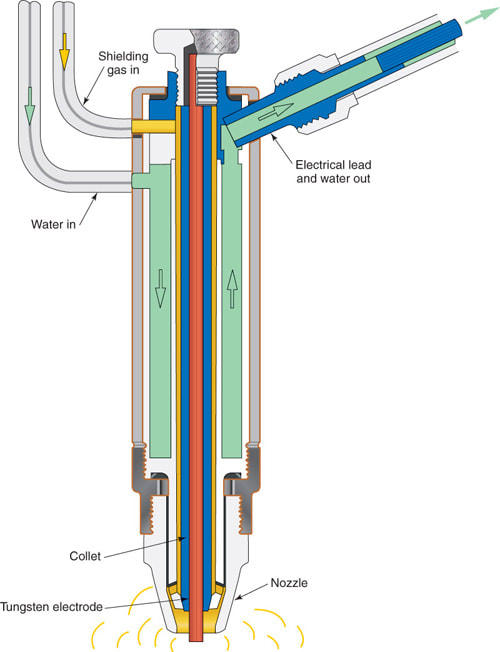

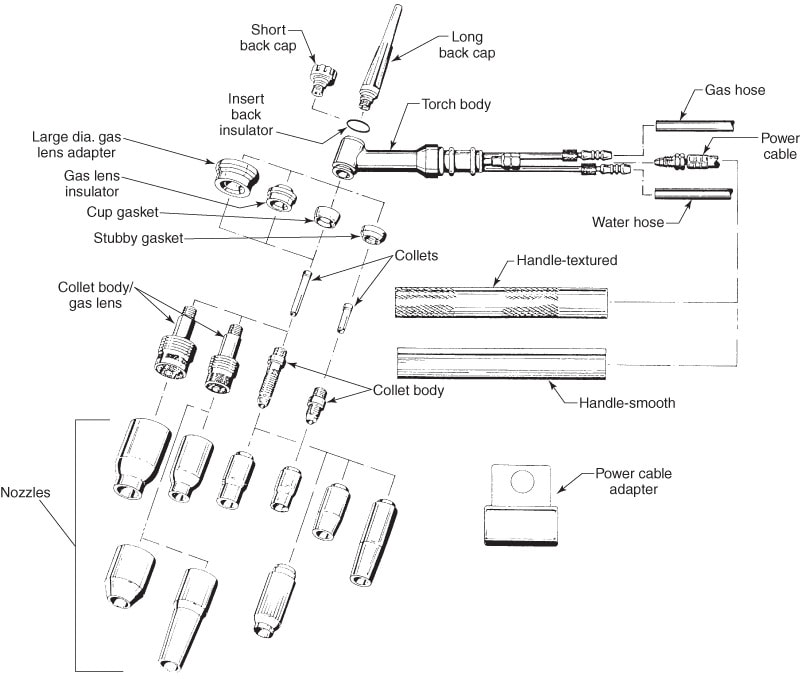

Figure 7-17 shows a cross section of a water-cooled torch. Figure 7-18 shows how different interchangeable parts of a water-cooled GTAW torch can be selected and assembled to modify the torch for different applications. These parts are also shown in Figure 7-19. Figure 7-14shows some of the torch parts as they would be assembled.

There are two basic torch designs. These are:

There are variations of the general access design. These variations allow a welder to select different parts of the torch for a specific job.

Gas tungsten arc welding torches come in many different designs, sizes, amperages, and shapes. Torches designed for lower amperages and light-duty use are cooled by the shielding gas flowing through the torch. Current capacity for the largest shielding gas-cooled torches is about 200A. Smaller gas-cooled torches carry significantly less current.

Torches used for higher amperages and those that are used to do a lot of welding at lower amperages are water-cooled. Most torches used in production and most torches used for continuous automatic welding are water-cooled. Figure 7-16 presents a side-by-side comparison of gas-cooled and water-cooled torches.

Figure 7-17 shows a cross section of a water-cooled torch. Figure 7-18 shows how different interchangeable parts of a water-cooled GTAW torch can be selected and assembled to modify the torch for different applications. These parts are also shown in Figure 7-19. Figure 7-14shows some of the torch parts as they would be assembled.

There are two basic torch designs. These are:

- Torches designed for general access: These torches usually use a long electrode and have a long cap. They also use standard collets, collet bodies, and nozzles. See Figure 7-15.

- Torches designed for work in areas where space is limited: These torches are called stubby or stubs. They use a very short electrode and have a very short cap. These also use stubby collets, stubby collet bodies, and stubby nozzles. See Figure 7-14.

There are variations of the general access design. These variations allow a welder to select different parts of the torch for a specific job.