7.4 Electrode Leads and Hoses Used for GTAW

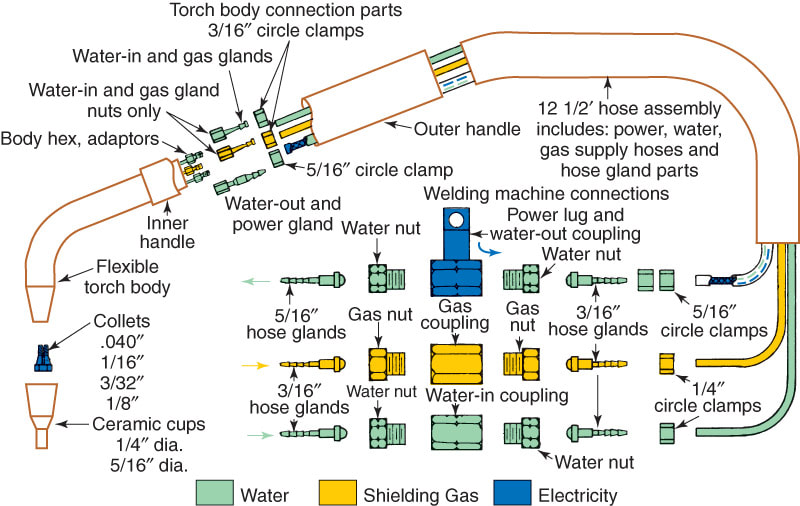

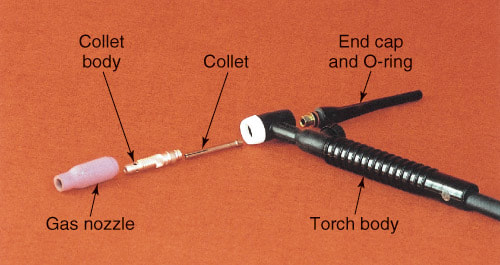

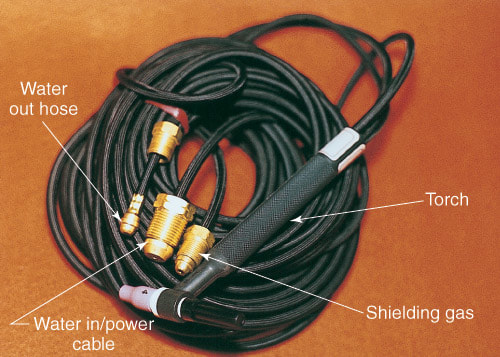

A water-cooled gas tungsten arc welding (GTAW) torch generally has two hoses and one combination hose and electrode lead connected to it. These hoses can be made of rubber or plastic materials. One hose carries the shielding gas to the torch. The second is a combinationwater hose and electrode lead. The electrode lead is a woven metal tube with excellent current carrying capabilities. This electrode lead is surrounded by a rubber or plastic tube. Welding current travels through the woven metal tube while water travels through the rubber or plastic tube. The third hose carries the water from the torch to the water drain. In a closed water system, the water is returned to the water cooling device and recirculated, Figure 7-10.

Figure 7-11 shows the hoses and fittings used in a typical water-cooled GTAW torch. The hoses in Figure 7-11 are enclosed in a single rubber sheath to keep them organized. Figure 7-12 shows a similar torch completely assembled for use. The hoses in Figure 7-12 are not enclosed in a sheath. Water-cooled torches are used with high currents or for high-duty-cycle welding.

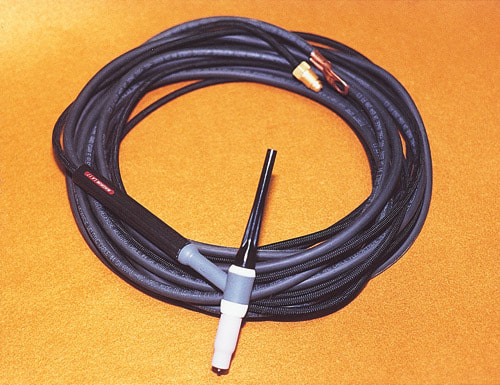

Light-duty GTAW torches are gas-cooled. These torches have only one hose connected to them. This hose is a combination electrode lead and shielding gas hose. The electrode lead can be a flexible cable or a woven tube. The shielding gas flows through a rubber or plastic tube which surrounds the electrode lead. Figure 7-13 shows an extremely light-duty GTAW torch, which is gas-cooled. Figure 7-14 and 7-15illustrate light-duty gas-cooled GTAW torches. Note the hose and cables on these torches.

A water-cooled gas tungsten arc welding (GTAW) torch generally has two hoses and one combination hose and electrode lead connected to it. These hoses can be made of rubber or plastic materials. One hose carries the shielding gas to the torch. The second is a combinationwater hose and electrode lead. The electrode lead is a woven metal tube with excellent current carrying capabilities. This electrode lead is surrounded by a rubber or plastic tube. Welding current travels through the woven metal tube while water travels through the rubber or plastic tube. The third hose carries the water from the torch to the water drain. In a closed water system, the water is returned to the water cooling device and recirculated, Figure 7-10.

Figure 7-11 shows the hoses and fittings used in a typical water-cooled GTAW torch. The hoses in Figure 7-11 are enclosed in a single rubber sheath to keep them organized. Figure 7-12 shows a similar torch completely assembled for use. The hoses in Figure 7-12 are not enclosed in a sheath. Water-cooled torches are used with high currents or for high-duty-cycle welding.

Light-duty GTAW torches are gas-cooled. These torches have only one hose connected to them. This hose is a combination electrode lead and shielding gas hose. The electrode lead can be a flexible cable or a woven tube. The shielding gas flows through a rubber or plastic tube which surrounds the electrode lead. Figure 7-13 shows an extremely light-duty GTAW torch, which is gas-cooled. Figure 7-14 and 7-15illustrate light-duty gas-cooled GTAW torches. Note the hose and cables on these torches.

|

|

|

|