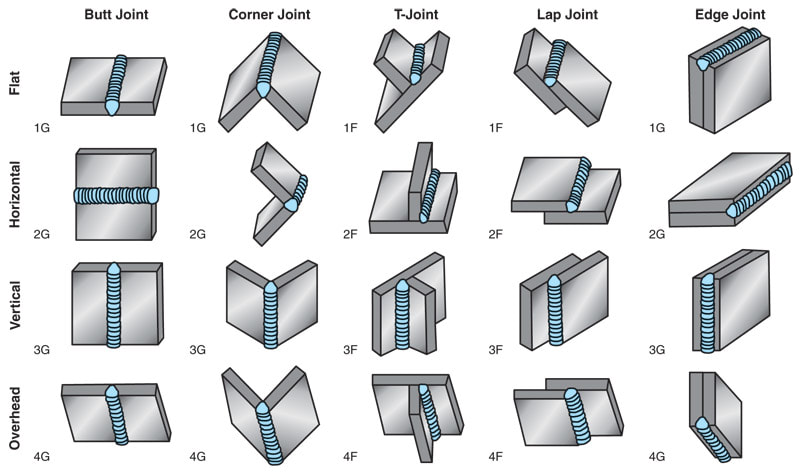

3.4 Welding Positions

Welders often must weld in a variety of positions. Welds may be made in the flat, horizontal, vertical, or overhead welding positions. See Figure 3-15. On welding drawings, these positions are often abbreviated in the tail of the welding symbol as F, H, V, and O. The American Welding Society refers to welding positions with a number and letter combination. Groove joints in the flat, horizontal, vertical, and overhead positions are referred to as 1G, 2G, 3G, and 4G, respectively. Fillet joints in the flat, horizontal, vertical, and overhead position are designated as 1F, 2F, 3F, and 4F, respectively.

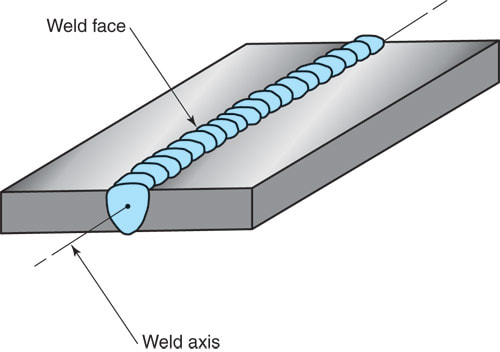

Welding positions are determined by the positions of the weld axis and weld face. Figure 3-16 shows the weld axis and weld face. The weld axis is an imaginary line running lengthwise through the center of a completed weld. The weld face is the exposed surface of a completed weld on the side on which the welding was done.

Welding positions are determined by the positions of the weld axis and weld face. Figure 3-16 shows the weld axis and weld face. The weld axis is an imaginary line running lengthwise through the center of a completed weld. The weld face is the exposed surface of a completed weld on the side on which the welding was done.