11.8 Welding Tips

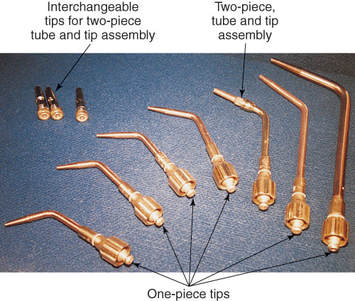

After the gases are mixed, they are fed through the tube, or barrel, of the body to the welding tip where combustion takes place. Most tips are made of copper. Since copper conducts heat rapidly, there is little danger of overheating and backfiring. Some tips are nickel-plated to help reflect heat and stay cooler. There are two types of tips, as shown in Figure 11-50:

Tip size and condition are important for proper welding. The orifice or hole in the end of the tip, must be the correct size. The tip size number indicates the orifice size and the relative gas rate the tip is capable of producing. In this text, torch tip size is indicated by number drill sizes.

- One-piece (tip and tip tube are one piece).

- Two-piece (tip and tip tube are separate). The tube is threaded so different tips can be attached).

Tip size and condition are important for proper welding. The orifice or hole in the end of the tip, must be the correct size. The tip size number indicates the orifice size and the relative gas rate the tip is capable of producing. In this text, torch tip size is indicated by number drill sizes.

Tips are subjected to both mechanical wear and flame erosion. As tips are removed and installed in a tip tube, the attaching threads may be subjected to considerable wear and abuse. Box-end type wrenches should be used to tighten and loosen tips to minimize damage. Pliers should never be used. Do not try to remove a hot tip from a tip tube. Allow the tip and tip tube to cool first. Also, do not install a cold tip in a hot tip tube.

Always use tips that are made for a particular torch. Some types of torches use a pliable, heat-resistant synthetic gasket to seal the joint between the tip tube and the torch. With this type of torch, no wrench is needed to install or service a tip. Hand-tightening is sufficient.

Avoid dropping a tip, since this could damage the seat that seals the joint. The flame end of the tip can be damaged by coming into contact with the welding work, the bench, or firebricks. This damage can roughen the end of the tip and cause the flame to burn with a “fishtail” appearance. The size and shape of the torch tip should never be altered.

Always use tips that are made for a particular torch. Some types of torches use a pliable, heat-resistant synthetic gasket to seal the joint between the tip tube and the torch. With this type of torch, no wrench is needed to install or service a tip. Hand-tightening is sufficient.

Avoid dropping a tip, since this could damage the seat that seals the joint. The flame end of the tip can be damaged by coming into contact with the welding work, the bench, or firebricks. This damage can roughen the end of the tip and cause the flame to burn with a “fishtail” appearance. The size and shape of the torch tip should never be altered.

11.8.1 Welding Tip Cleaners

As mentioned before, welding tips are sometimes subject to considerable abuse. The orifice must be kept smooth and clean if the tip is to perform satisfactorily. During the welding process, molten metal can “pop” and throw molten droplets into the tip orifice. Carbon deposits and slag must be removed regularly from tips to ensure good performance. Be careful not to enlarge or scar the orifice when cleaning a welding tip.

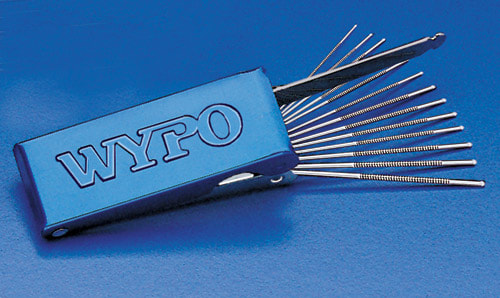

Special welding tip cleaners have been developed to satisfactorily service a welding tip. The cleaner consists of a series of broaching wires (a broach is a tool used to shape a hole) that corresponds to the diameters of tip orifices. See Figure 11-51. These wires are packaged in a holder, which makes their use safe and convenient. Figure 11-52 shows a tip cleaner in use.

Special welding tip cleaners have been developed to satisfactorily service a welding tip. The cleaner consists of a series of broaching wires (a broach is a tool used to shape a hole) that corresponds to the diameters of tip orifices. See Figure 11-51. These wires are packaged in a holder, which makes their use safe and convenient. Figure 11-52 shows a tip cleaner in use.

Some welders prefer to use a drill bit of the correct size to clean welding tip orifices. If a drill bit is used, cleaning must be done very carefully, so that the orifice is not enlarged, bellmouthed, reamed out-of-round, or otherwise damaged.

The flame end of the tip must be clean and smooth. To create a properly shaped flame, the tip's surface must be at a right angle to the centerline of the tip orifice. A 4″ mill file is commonly used to recondition the orifice end of the welding or cutting torch tip, as shown in Figure 11-53.

The flame end of the tip must be clean and smooth. To create a properly shaped flame, the tip's surface must be at a right angle to the centerline of the tip orifice. A 4″ mill file is commonly used to recondition the orifice end of the welding or cutting torch tip, as shown in Figure 11-53.