11.5 Welding Hoses

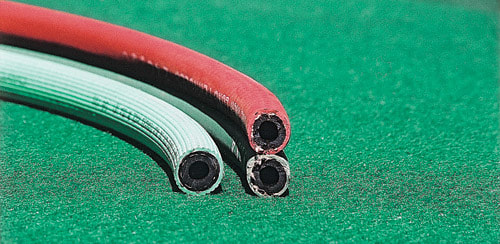

Hoses are built in several layers for strength. The inner layer is generally a very good grade of gum rubber. This layer is often surrounded by several layers of reinforced materials. The outer layer or covering is made of a colored rubber or plastic, which may be ribbed to provide a long-wearing surface. See the ribbed, green oxygen hose in Figure 11-35. Hoses are manufactured in three common colors: black, green, and red.

The use of these colors is not standardized. However, the red hose is usually used for carrying acetylene or other fuel gases. Either the green or the black hose is used to carry the oxygen. The hose is specified according to its inside diameter (ID), and comes in several sizes. Inside diameter is the measurement of length taken from the inside of a tube, pipe, hose, or other round object. The inside diameter is the commonly used measure for sizing pipe or hose. The most common sizes are 3/16″, 1/4″, and 5/16″ (4.8mm, 6.4mm, and 7.9mm).

The size to be used depends on the size of the torch, and the length of hose needed. The 3/16″ (4.8mm) ID hose is very flexible and light, and is used for light duty welding. The size (inner diameter) of the hoses should be increased if the hose is excessively long. Double hoses, like the one shown in Figure 11-36 are also available. These are composed of two separate hoses fused together along most of their length, but separated at the ends. The design prevents the individual hoses from becoming tangled together.

Suppliers usually furnish hoses in 25″ (7.62m) lengths. However, reels specially designed for oxygen/acetylene hose can efficiently handle much longer lengths of hose, Figure 11-37.

The use of these colors is not standardized. However, the red hose is usually used for carrying acetylene or other fuel gases. Either the green or the black hose is used to carry the oxygen. The hose is specified according to its inside diameter (ID), and comes in several sizes. Inside diameter is the measurement of length taken from the inside of a tube, pipe, hose, or other round object. The inside diameter is the commonly used measure for sizing pipe or hose. The most common sizes are 3/16″, 1/4″, and 5/16″ (4.8mm, 6.4mm, and 7.9mm).

The size to be used depends on the size of the torch, and the length of hose needed. The 3/16″ (4.8mm) ID hose is very flexible and light, and is used for light duty welding. The size (inner diameter) of the hoses should be increased if the hose is excessively long. Double hoses, like the one shown in Figure 11-36 are also available. These are composed of two separate hoses fused together along most of their length, but separated at the ends. The design prevents the individual hoses from becoming tangled together.

Suppliers usually furnish hoses in 25″ (7.62m) lengths. However, reels specially designed for oxygen/acetylene hose can efficiently handle much longer lengths of hose, Figure 11-37.

Hoses should never be interchanged, carrying first one gas and then another gas. If oxygen were to pass down a used acetylene hose, a combustible mixture would form.

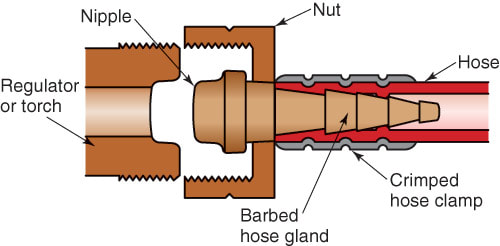

To prevent this, special precautions are used when attaching the hose to the regulators and torch. The hose is connected to a barbed hose gland (which has a nipple at one end and barbs at the other end) by means of a hose clamp. After inserting the barbed end of the hose gland into the welding hose, the hose clamp is crimped onto the hose using a special crimping tool. See Figure 11-38. The nipple end that is protruding from the end of the welding hose is then fastened to a regulator or torch by means of a nut as shown in Figure 11-39. Both the oxygen nipple and the acetylene nipple have a smooth, rounded face that serves as a sealing surface. A properly assembled welding hose connected to an oxyacetylene welding torch is shown in Figure 11-40.

To prevent this, special precautions are used when attaching the hose to the regulators and torch. The hose is connected to a barbed hose gland (which has a nipple at one end and barbs at the other end) by means of a hose clamp. After inserting the barbed end of the hose gland into the welding hose, the hose clamp is crimped onto the hose using a special crimping tool. See Figure 11-38. The nipple end that is protruding from the end of the welding hose is then fastened to a regulator or torch by means of a nut as shown in Figure 11-39. Both the oxygen nipple and the acetylene nipple have a smooth, rounded face that serves as a sealing surface. A properly assembled welding hose connected to an oxyacetylene welding torch is shown in Figure 11-40.

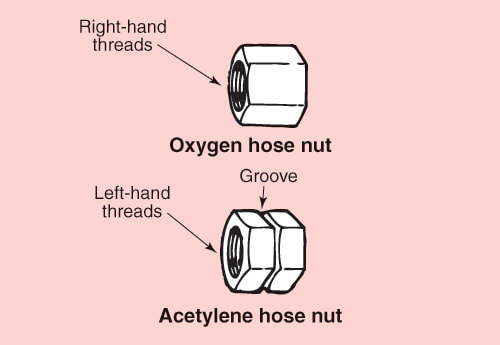

The nut used to connect the nipple on the oxygen hose to the torch or regulator has right-hand threads. The oxygen nut may also be marked “OXY.” The six sides of the oxygen nut are flat and smooth.

The regulator and hose fittings used for acetylene have left-hand threads, and the hose fitting nut may be marked "ACE." An acetylene hose fitting nut also has a groove machined around its six sides. Figure 11-41 illustrates the differences between oxygen and acetylene hose nuts.

Hoses must be carefully handled to prevent accidents. They should not be allowed to come in contact with any flame or hot metal. Care should be taken to prevent hoses from being kinked sharply. Kinking a hose might crack the fabric and allow the pressure to burst the hose. A kink will also hinder the gas flow. When the equipment is not being used, hoses should be hung away from the floor and away from things that might damage them. During welding, the hoses should always be protected from falling objects, vehicles running over them, and from being stepped on, as these actions can also damage the hoses.

Hose reels are available. They are usually spring-loaded and roll up the hose into the container when the station is not being used.

The regulator and hose fittings used for acetylene have left-hand threads, and the hose fitting nut may be marked "ACE." An acetylene hose fitting nut also has a groove machined around its six sides. Figure 11-41 illustrates the differences between oxygen and acetylene hose nuts.

Hoses must be carefully handled to prevent accidents. They should not be allowed to come in contact with any flame or hot metal. Care should be taken to prevent hoses from being kinked sharply. Kinking a hose might crack the fabric and allow the pressure to burst the hose. A kink will also hinder the gas flow. When the equipment is not being used, hoses should be hung away from the floor and away from things that might damage them. During welding, the hoses should always be protected from falling objects, vehicles running over them, and from being stepped on, as these actions can also damage the hoses.

Hose reels are available. They are usually spring-loaded and roll up the hose into the container when the station is not being used.